Product Features

-

Marks remain intact and legible for the lifetime of the product, providing a reliable solution for long-term identification and branding needs.

-

Markings easily readable and visually striking, enhancing the visibility and aesthetic appeal of your product.

-

The markings are resistant to wear, abrasion, and environmental factors, ensuring they stay intact and legible even under harsh conditions.

Why Brilliance Laser Inks?

Exceptionally adaptable laser marking inks to create high quality permanent mark on a various metal surfaces.

Liquid Ready as the name describes contains pre-measured powder product and is ready to add denatured alcohol without any hassle. It is also compatible to preval spray system which makes the product convenient to use.

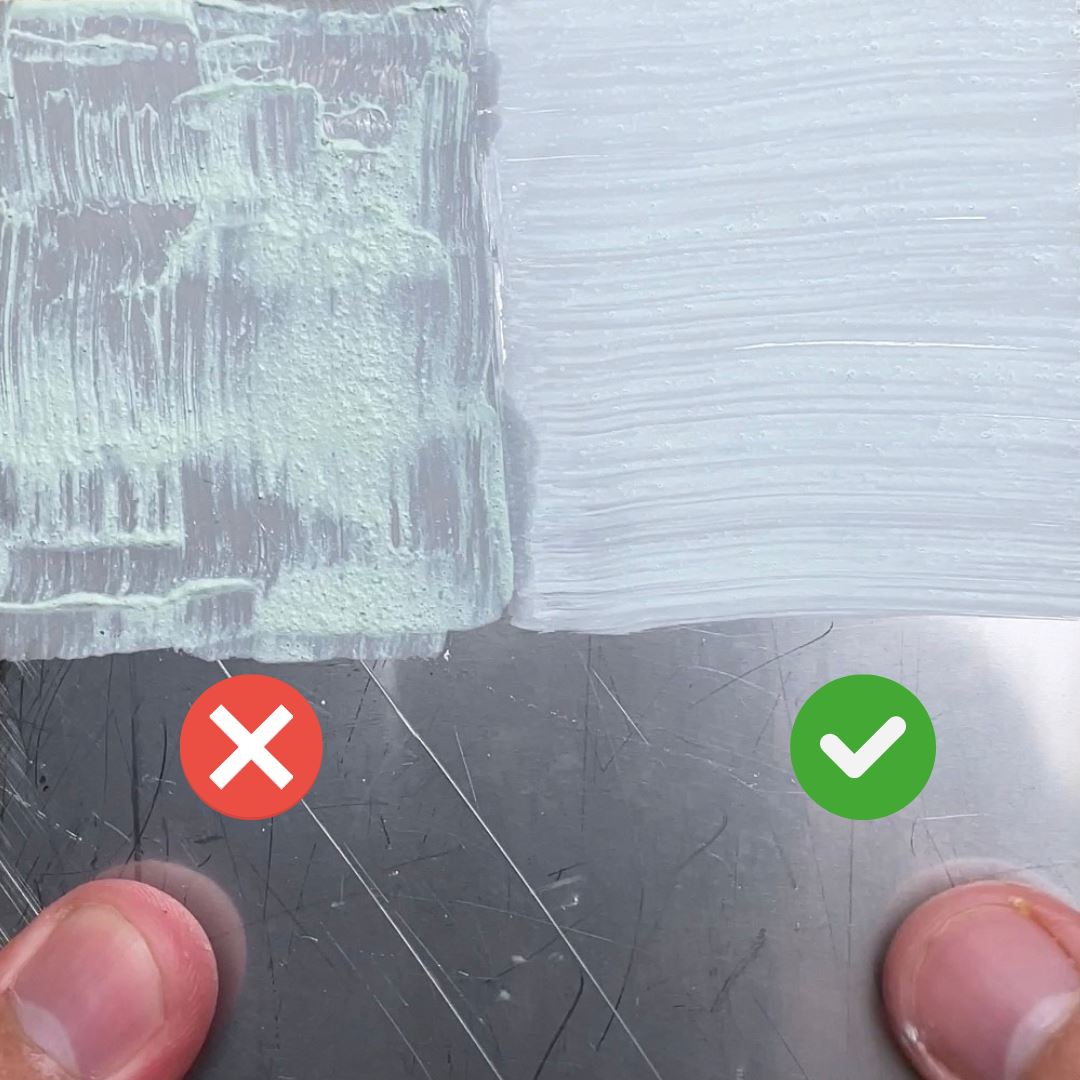

How To Apply Liquid Ready?

Understanding these detailed steps on how to correctly apply will significantly enhance the quality of your laser marking projects.

Results!

Using Brilliance Laser Inks on a different metal substrate delivers high-quality, durable, and visually appealing results that enhance the value and aesthetic of the product.